ADD: No.689 Jingxing 1st road,Pinghu Jiaxing,Zhejiang Province,China

Integrating pneumatic air cylinders into automated structures or machinery can substantially beautify their performance and productivity. Pneumatic structures offer advantages consisting of simplicity, versatility, and cost-effectiveness. By knowledge the essential standards and considerations, you could efficiently layout and put in force pneumatic systems for green operation.

1. System Design:

a) Identify the duties: Determine the specific obligations that require automation. This may want to variety from simple linear movement, clamping or unclamping gadgets, pushing or pulling masses, and so forth.

B) Calculate the desired pressure and velocity: Determine the pressure and speed required to perform the diagnosed tasks. Force is determined by using the load being moved, and velocity impacts the general cycle time.

C) Cylinder choice: Select the proper cylinder size based totally at the calculated force requirement. Cylinder sizes are typically targeted with the aid of their bore and stroke dimensions.

D) Control device layout: Decide on the manage approach for the system. This will be manual manage using valve operators or automatic control using sensors, programmable common sense controllers (PLCs), or similar gadgets.

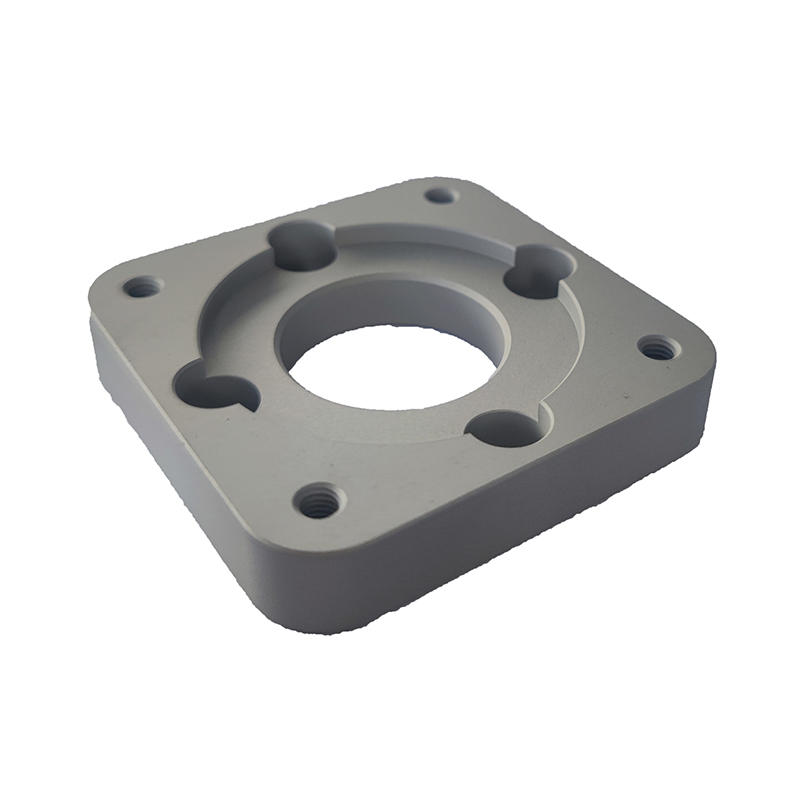

2. Cylinder Mounting:

a) Mounting holes: Ensure that the cylinder has the specified mounting holes for smooth integration into the system. These holes can be positioned at either give up or at the facet of the cylinder.

B) Proper alignment: Mount the cylinder cautiously to make certain right alignment with the specified project and avoid any potential misalignment problems at some stage in operation.

C) Mounting brackets: Use suitable mounting brackets to securely attach the cylinder to the machinery or device. These brackets must be designed to withstand the forces and vibrations exerted during operation.

Three. Air Supply:

a) Compressed air excellent: Ensure the air deliver is easy, dry, and at the precise stress. Dirty or wet air can result in harm or decreased performance of the pneumatic additives.

B) Regulating pressure: Use a strain regulator to adjust the air pressure supplied to the gadget. This allows control the force and speed of the cylinders, ensuring specific and steady operation.

C) Pressure alleviation valve: Install a pressure comfort valve to protect the system from overpressurization, which could motive damages to the system or endanger operators.

4. Control and Sensing:

a) Valves: Select the precise valves based on the desired manage approach (manual or computerized). Directional control valves allow air to circulate and out of the cylinder, controlling the direction of movement.

B) Flow manage valves: Use waft manipulate valves to modify the velocity of the cylinder's motion. This allows in reaching unique and managed motion.

C) Sensor integration: Install sensors to display the position, velocity, or pressure all through operation. This lets in for manage and guarantees the device operates within favored tolerances.

5. Maintenance and Safety:

a) Lubrication: Regularly lubricate the cylinders and different pneumatic additives to lessen friction and wear, making sure clean operation.

B) Regular inspections: Periodically look into the cylinders for, damaged seals, or other signs of wear and tear. Replace any defective additives directly to keep away from downtime or ability hazards.

C) Safety measures: Implement appropriate protection measures to defend operators and save you injuries. Consists of putting in safety guards, emergency stop buttons, and following applicable protection standards and policies.

6. System Integration:

) Testing and validation: Perform thorough checking out and validation of the whole gadget earlier than deployment. This consists of checking for proper operation, required pressure, and speed, as well as verifying that the system meets protection standards.

B) System monitoring: Implement a machine monitoring mechanism to make sure non-stop operation and discover any capability troubles or screw ups which can arise within the device.

C) Training: Train the operators and preservation employees at the proper operation and renovation of the pneumatic gadget. This allows ensure efficient utilization and toughness of the system.

In conclusion, integrating pneumatic air cylinders into automatic structures or machinery calls for careful attention of system design, cylinder mounting, air supply, control strategies, sensing, preservation, safety measures, and system integration. By following those tips, you'll gain green operation even as harnessing the blessings of pneumatic structures.

中文简体

中文简体

English

English

Español

Español