Who

we are

Who

we are

Founded in Fujian in 1993, producing copper parts.

In 1998, the production was transformed, and the production of zinc and aluminum die-casting parts began.

In 1998, the production was transformed, and the production of zinc and aluminum die-casting parts began.

2004 Obtained the ISO9001 quality system for the first time.

2009 The construction of Shanghai Jinshan factory was completed and put into use.

2012 Started production of die castings for the automotive industry.

2017 Zhejiang Bangye Automation Technology Co., Ltd. was established.

In 2018, the ERP system began to be used.

In 2020, the new factory in Pinghu, Zhejiang was completed and put into use.

In 2021, it was awarded as a high-tech enterprise and a small and medium-sized technological enterprise in Zhejiang Province.

In 2022, passed ISO9001, ISO14001, ISO45001 and other systems.

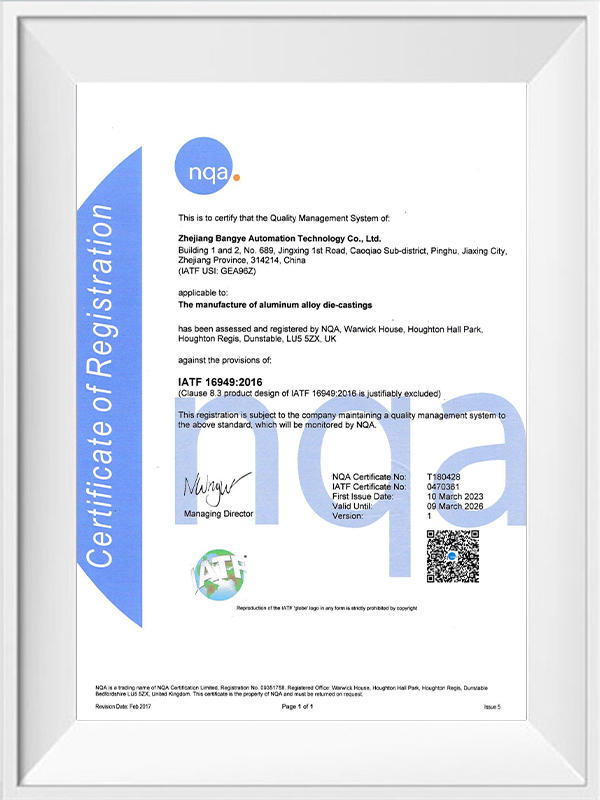

Passed the IATF16949 system in 2023.

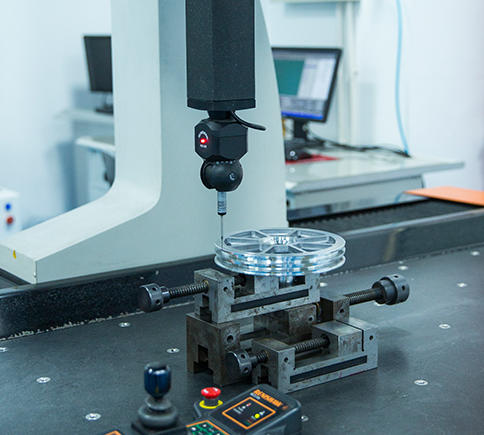

Quality

Assurance

The staff of quality department occupies

10-15% of all the staffs (20-25 P)

IQC (Incoming quality control for raw material)

IPQC(In process quality control)

OQC(Outing quality control before delivery)