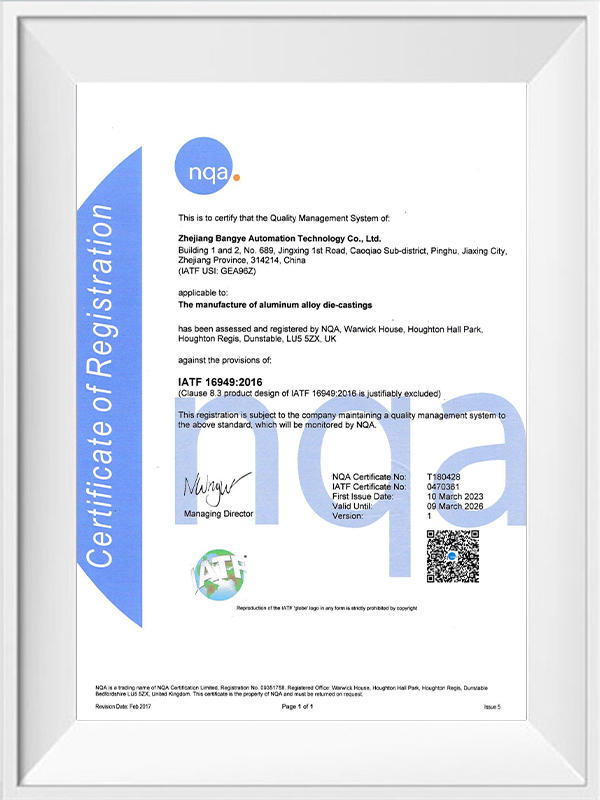

Who

we are

Who

we are

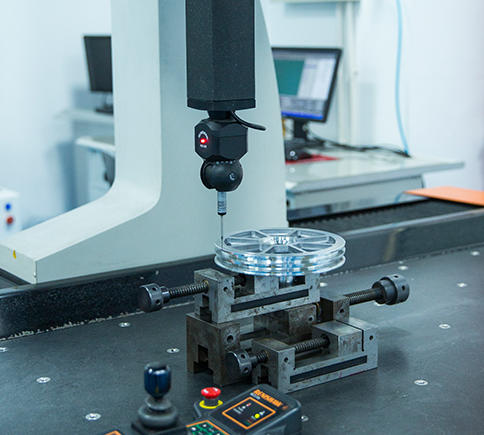

Pneumatic cylinder accessories are designed to be compatible with various types of pneumatic cylinders, but it's important to note that compatibility can vary depending on the specific accessories and cylinders involved.

Pneumatic cylinder accessories encompass a wide range of components that can enhance the performance, functionality, and safety of pneumatic cylinder systems. Some common examples include mounting brackets, rod clevises, pivot brackets, limit switches, flow controls, pressure regulators, and cushioning devices.

When selecting accessories for a pneumatic cylinder, it's crucial to consider factors such as the cylinder type (single-acting, double-acting), cylinder bore size, stroke length, operating pressure, and the specific application requirements. Different cylinder manufacturers may have their own proprietary designs and specifications, so it's important to consult the manufacturer's documentation or contact them directly to ensure compatibility between the cylinder and the accessories you intend to use.

Pneumatic cylinder accessories can contribute to improving energy efficiency in several ways. Here are some ways in which these accessories can help:

Flow Control Valves: Flow control valves regulate the speed of the pneumatic cylinder's piston movement. By adjusting the flow rate of compressed air into and out of the cylinder, they can control the speed of operation. This allows for precise and optimized movement, reducing unnecessary energy consumption and preventing excessive wear and tear.

Pressure Regulators: Pressure regulators help maintain consistent and optimal operating pressure in the pneumatic system. By keeping the pressure within the required range, they prevent energy waste resulting from excessive pressure. Regulators ensure that only the necessary amount of compressed air is used, reducing energy consumption and minimizing system leaks.

Quick Exhaust Valves: Quick exhaust valves are designed to rapidly release the exhaust air from the pneumatic cylinder. By allowing air to escape more quickly, these valves minimize the back pressure within the system. This decreases the energy required for the cylinder to return to its original position, resulting in faster cycle times and reduced overall energy consumption.

Cushioning Devices: Cushioning devices, such as adjustable pneumatic cushions, help reduce the impact and deceleration of the piston at the end of its stroke. By absorbing energy and providing a controlled deceleration, cushioning devices prevent abrupt stops, vibration, and excessive stress on the cylinder and the connected components. This reduces energy losses and extends the lifespan of the equipment.

Air Saving Valves: Air saving valves, also known as shuttle valves or bypass valves, enable the controlled release of compressed air from the cylinder during non-working strokes. Instead of exhausting the air into the atmosphere, these valves redirect it to another part of the system or back to the air compressor. This feature reduces the amount of compressed air consumed, resulting in energy savings.

Sensors and Feedback Devices: Adding sensors and feedback devices to pneumatic cylinders allows for more precise control and monitoring of their operation. By providing accurate position feedback, pressure sensing, or load sensing, these devices enable the system to optimize energy usage. With the help of feedback signals, the control system can adjust parameters such as pressure, flow, and speed to match the specific requirements of the application, minimizing energy waste.