ADD: No.689 Jingxing 1st road,Pinghu Jiaxing,Zhejiang Province,China

A small pneumatic punching press machine is a mechanical device used for punching holes or shapes in various materials such as paper, plastic, leather, or thin metals. It utilizes pneumatic power to generate the force needed for punching.

Here's a general overview of how a small pneumatic punching press machine works:

Pneumatic Power Source: The machine is powered by compressed air supplied from an external source such as an air compressor. The air is typically regulated to a specific pressure range to ensure consistent operation.

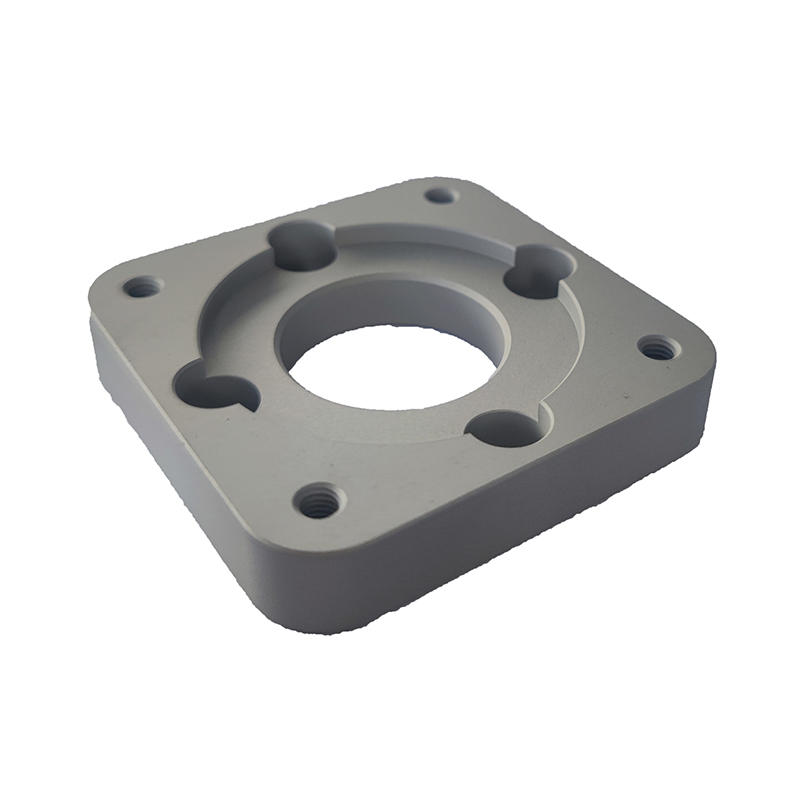

Punching Mechanism: The machine consists of a punching mechanism that delivers the force to create the hole or shape. This mechanism usually consists of a punch and a die. The punch is the tool that applies the force, and the die provides a support surface for the material being punched.

Control System: The machine has a control system that allows the operator to initiate the punching process. This can be a foot pedal or a button that activates the pneumatic system when pressed.

Material Placement: The material to be punched is placed on the die beneath the punch. It is important to position the material correctly to ensure accurate and consistent punching.

Pneumatic Actuation: When the operator initiates the punching process, the control system triggers the pneumatic actuator. The actuator releases compressed air into a cylinder, creating a piston-like motion.

Punching Force: The compressed air pushes the piston or ram forward, driving the punch through the material and into the die. The force generated by the pneumatic actuator determines the strength and depth of the punch.

Material Removal: After the punch has penetrated the material, the piston retracts, pulling the punch out of the material. The punched-out piece or waste material may drop down or be collected separately, depending on the machine's design.

Repeat Process: The punching process can be repeated multiple times by repositioning the material and initiating the machine again. This allows for the creation of multiple holes or shapes in a consistent manner.

It's worth noting that the specific design and operation of a small pneumatic punching press machine may vary depending on the manufacturer and the intended application. However, the fundamental principle of using compressed air to generate punching force remains consistent across different machines.

中文简体

中文简体

English

English

Español

Español