ADD: No.689 Jingxing 1st road,Pinghu Jiaxing,Zhejiang Province,China

Pneumatic punching presses are machines that use compressed air as their power source to perform various types of punching, cutting, and forming operations on materials like metal, plastic, paper, or fabric. These machines are commonly used in manufacturing, fabrication, and metalworking industries for tasks such as hole punching, stamping, shearing, and bending. Here's how they work:

Compressed Air Source: Pneumatic punching presses rely on a source of compressed air. This compressed air is typically generated using a compressor, which takes in ambient air and pressurizes it.

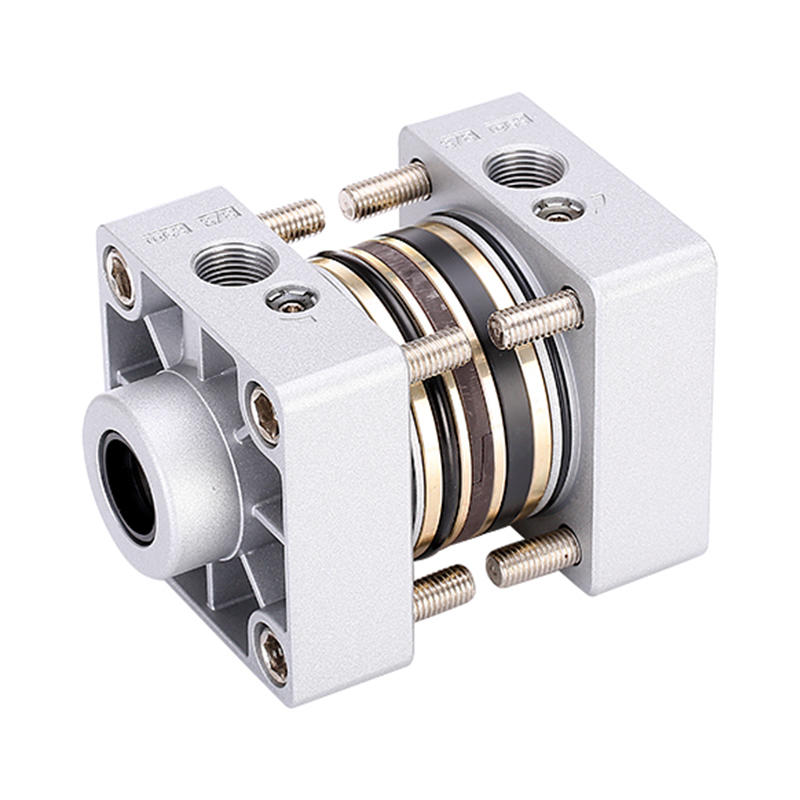

Pneumatic System: The compressed air is then transported through a network of pipes and hoses to the pneumatic punching press. Within the press, the air is regulated and controlled using valves and other components.

Actuation: When the operator initiates the punching or cutting operation, the pneumatic system directs the compressed air to an actuator or cylinder. The cylinder converts the pressure from the compressed air into mechanical force.

Tooling: Attached to the actuator is a set of specialized tooling, such as a punch and die. The punch is the tool that makes contact with the workpiece, while the die provides support. The shape and size of the punch and die determine the type of operation that the press can perform.

Operation: The actuator, powered by the compressed air, moves the punch downward with great force. This force is applied to the workpiece, causing it to deform, cut, or shape as desired. The operator may control the force and duration of the operation based on the specific requirements.

Safety Features: Pneumatic punching presses often come equipped with safety features such as two-handed controls, guards, and emergency stops to ensure operator safety during operation.

Advantages of using compressed air in pneumatic punching presses include:

Adjustable Force: Compressed air systems allow for easy adjustment of the force applied during the punching or cutting operation by regulating the air pressure.

Speed: Pneumatic presses can operate at high speeds, making them suitable for mass production.

Reliability: Compressed air is a reliable power source, and pneumatic systems are known for their durability and low maintenance requirements.

Versatility: Pneumatic punching presses can be used for a wide range of materials and applications, with the ability to change tooling for different tasks.

However, there are also some limitations, such as the need for a compressed air source and potential energy inefficiencies compared to other power sources like hydraulic systems. The choice between pneumatic, hydraulic, or electric punching presses depends on the specific requirements of the application and the materials being processed.

中文简体

中文简体

English

English

Español

Español